Inspection and Testing

It can be tricky to stay up to date with the relevant legal requirements and keep all equipment operating safely but we are here to simplify this for you.

With many years' experience behind us, we have the specialist knowledge to deal with inspections, testing and certification, with a service that is designed around the specific needs of performance venues. We can advise you on what should be tested and how often, as well as helping you to create a cost-effective plan to keep your venue compliant and safe.

Our comprehensive inspection and testing services include:

Find more details on our inspection and testing services below or contact us to see how we can help you.

Do you know which legislation and guidance is applicable to your venue? Take a look at our fact sheet for more information.

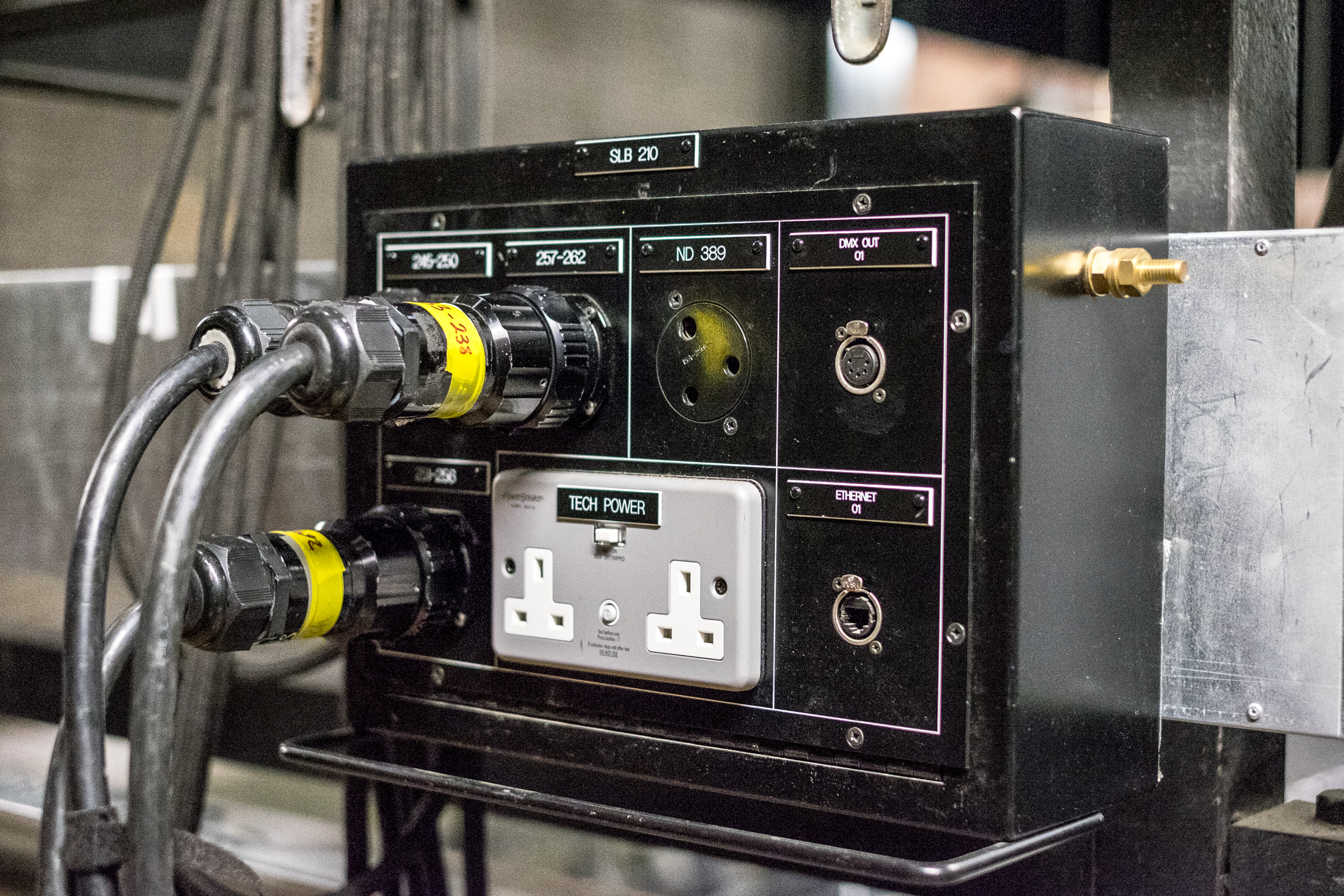

Fixed Wire Testing -

Electrical Installation Condition Report

Our fixed wire EICR electrical inspection examines everything from the distribution board supplying your venue to the outgoing circuits within them. After our visit, we provide you with a detailed report highlighting our observations and any defects found. This follows the requirements by the NICEIC (National Inspection Council for Electrical Installation Contracting). Our fixed wire inspection covers (as required):

Dimming circuits

Patch bays

Technical Power circuits

Independent and non-dim circuits

Sound power circuits

Temporary supplies

'Blues' and working light circuits

Integrated house light systems

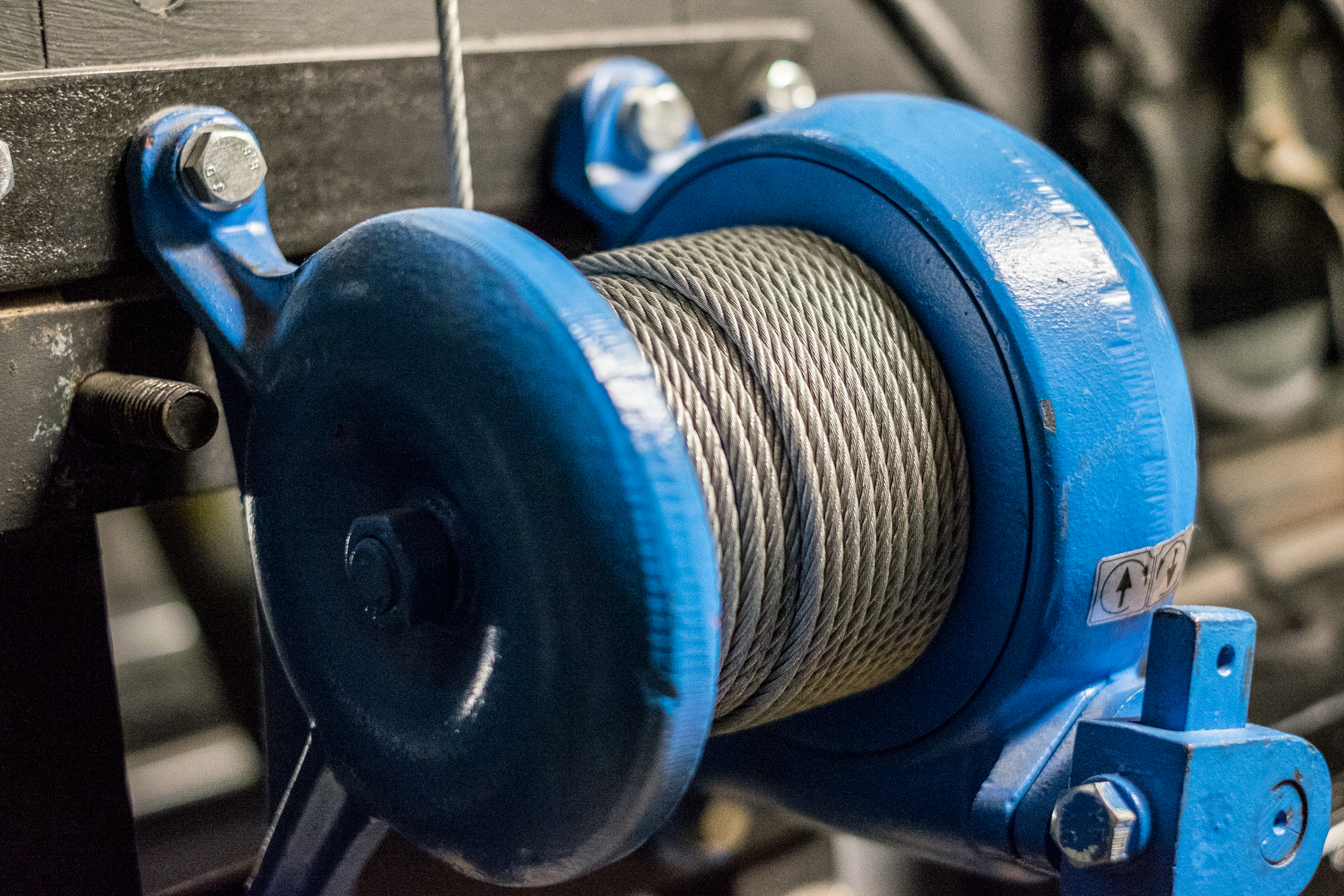

Rigging Inspections -

LOLER and PUWER

The legislation covering a mechanical installation can vary greatly, depending on the nature of the installation, so it is always best to contact us for advice on this.

Our rigging inspections are tailored to the type of installation you have and we can help with simple fixed bars, through to hemp, counterweight, winched raise-and-lower systems (which require LOLER inspections) and load testing.

Please see below for additional information on the types of inspection we cover.

Whatever your requirements, the fundamentals remain the same. Our experienced engineers will perform a thorough visual inspection of the rig, looking for signs of wear and tear, deformity, overloading, poor installation or use, and incorrect or unrated components. During their inspection they will tighten accessible components to ensure it is maintained.

After our visit, we provide you with a detailed report that highlights our observations and any defects.

Our range of available inspections can be viewed below.

Fixed Equipment

(non raise and Lower)

Lighting Bars and Grids

Curtain Tracks

Scenery Bars

'Leg' Bars

Raise-and-lower installations

(equipment able to raise or lower a load)

Hemp Sets

Manual Winch Sets

Drill-Drive Winch Sets

Electric Winch Sets

Counterweight Sets

Chain Hoists

Truss Systems

Rigging stock

(individual accessories that are stored and used as required)

Roundslings and Webbing Slings

Shackles

Wire Rope Assemblies

Truss Adaptors

Eye-bolts and Eye-nuts

Pulleys

Scenery Flying Fittings

Lifting Chains

Safety Curtains and Drenchers

Classic Halls Safety Curtain Installations – arrested with an air ram

Modern Safety Curtain Installations – arrested with a hydraulic damper

Drencher Systems

Haystack Lantern Light Smoke Vents

Orchestra Pit and Forestage Lifts

Scissor Lift Systems

Screw-jack Systems

Serapid Systems

Retractable Seating

Manually operated

Electrically operated

Fixed and Mobile Systems

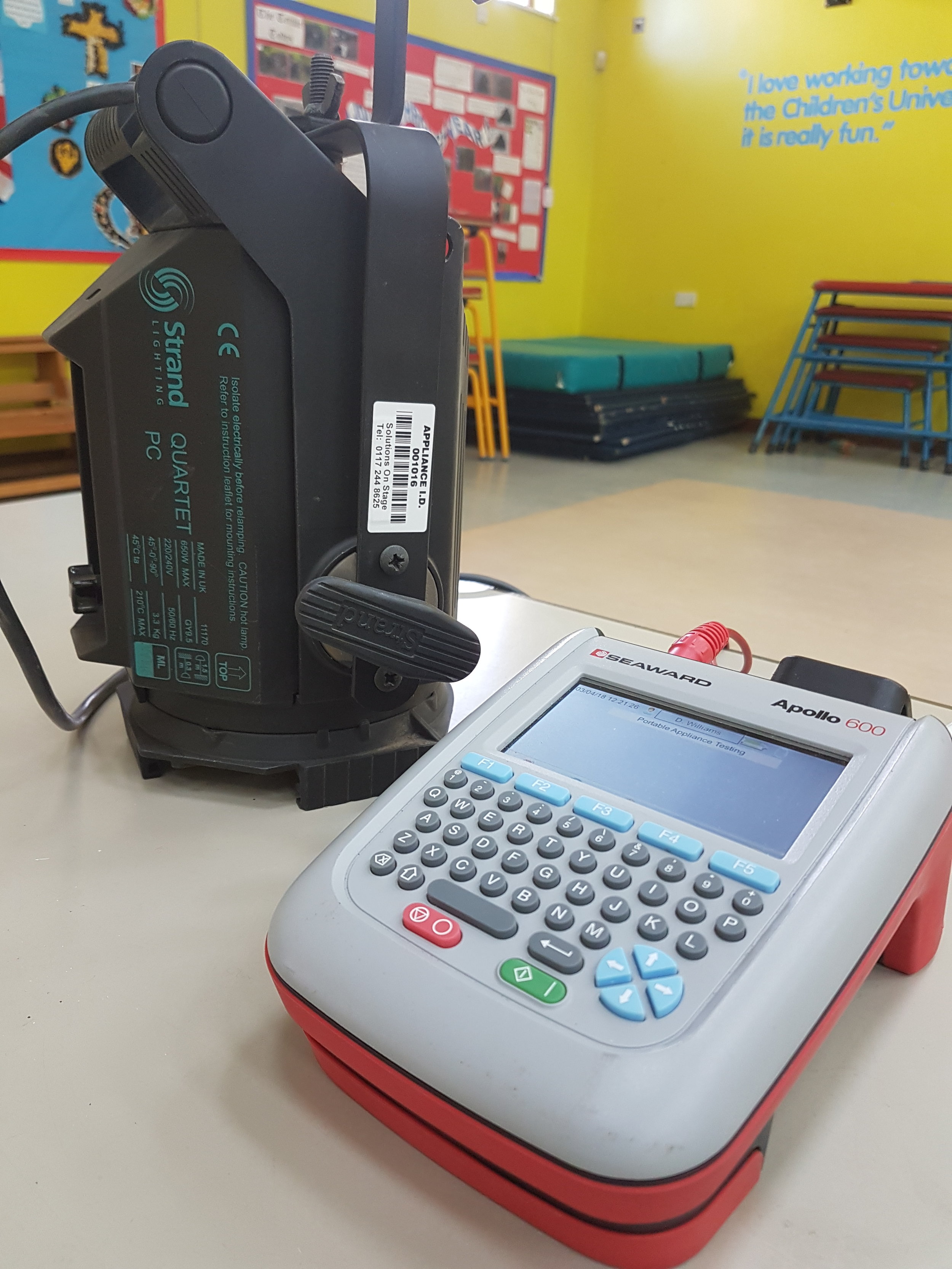

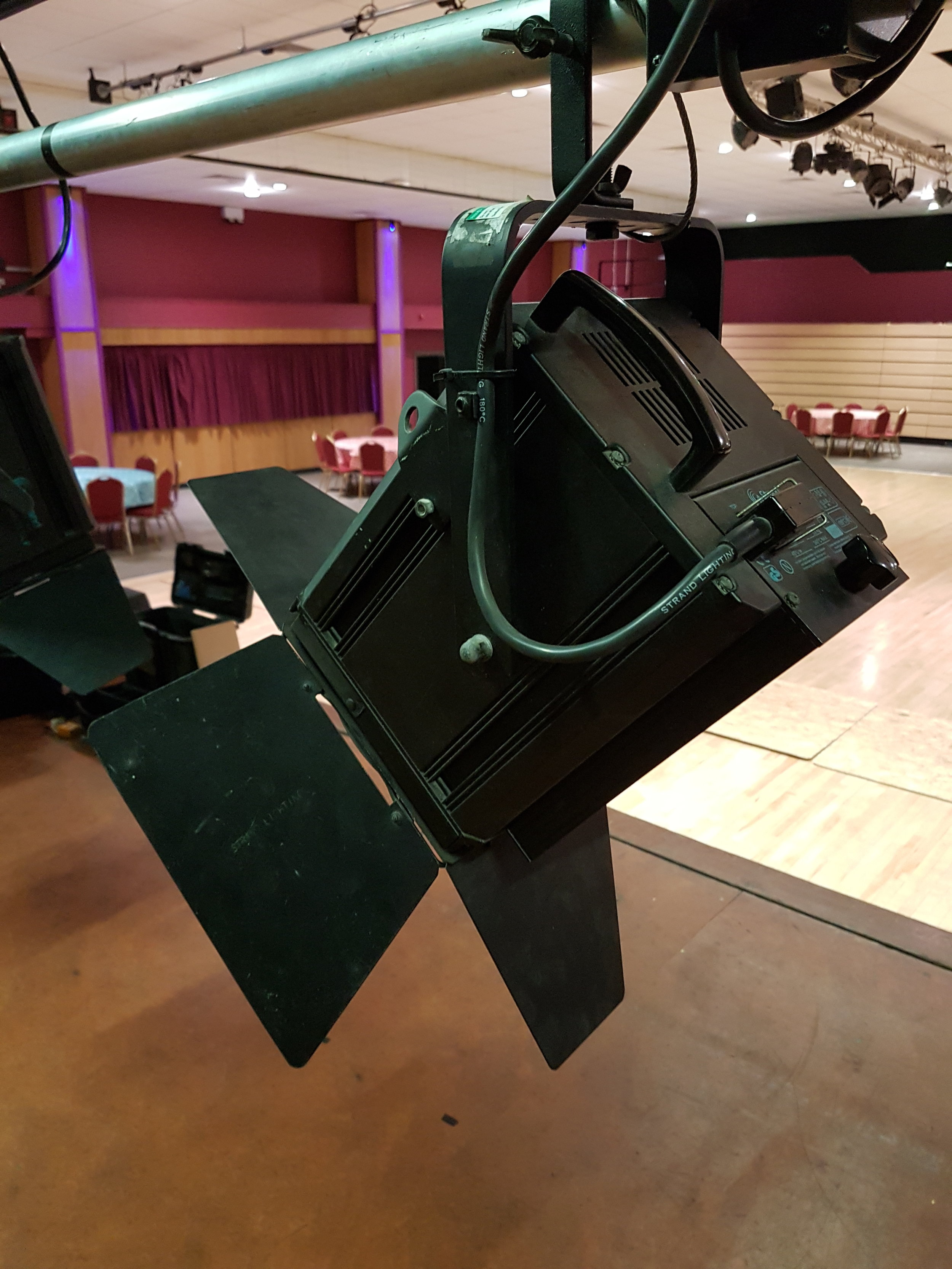

Portable Appliance Testing

Did you know that 80% of faults found during a Portable Appliance Test are picked up during the visual inspection? The PAT machine may be complex but you can't beat experience when it comes to picking up faults. We understand the equipment we are inspecting: these tests generally take a little longer to complete than a kettle or a toaster, but that extra time means our PAT inspections are more than just an exercise in box-ticking.

All of our teams are trained for work-at-height, and have PASMA and IPAF certification (where required). After our visit you will receive a detailed asset report highlighting passes and fails.

Examples of the types of equipment we specialise in are:

Lanterns

Moving lights

Powered speakers

Extension cables

Multi-way adaptors

Control room equipment

Socapex and Lectraflex

Access Equipment Inspections

With many years’ experience behind us of using and training on a variety of access equipment, we can offer detailed and comprehensive inspections of your venue’s owned access equipment. After our visit, we provide you with a detailed report that highlights our observations and any defects found.

Access equipment inspections can include:

Combination and extension ladders

Step ladders

Fixed ladders

Access tower components

Personal Protective Equipment (PPE) Inspections

The HSE and Work at Height Safety Association recommend that detailed inspections of PPE - that forms part of fall protection systems - is carried out by a competent person every six months (three months in harsh environments), and that the inspection be recorded. The use, environment, history, and manufacturers’ instructions and recommendations must all be considered. Some equipment is given a lifespan or obsolescence date by the manufacturer. Our experienced inspectors are capable of identifying and assessing defects and issues, and reporting on their significance and the continued use of the equipment.

We can offer inspections on the following PPE (as required):

Harnesses

Lanyards and strops

Connectors

Catenary wire systems

Fall arrest systems

Rescue systems

Please contact us to discuss the inspections and testing requirements for your venue.

We can also support you after we have completed our inspection - take a look at our maintenance and remedials and small works services for more information.